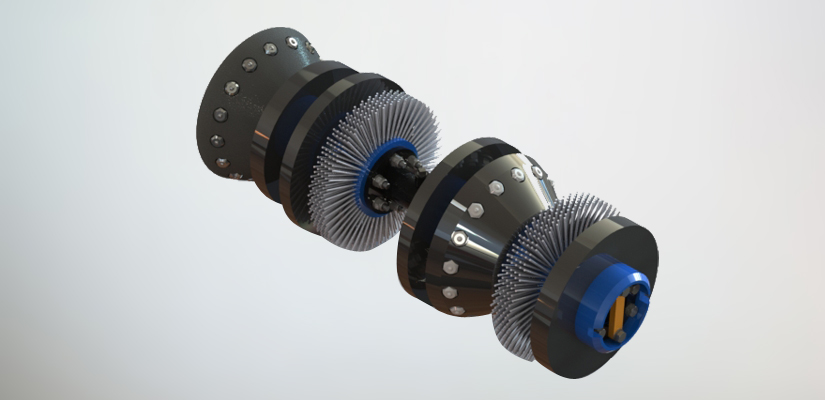

Generally, the studded or pin-wheel scraper is designed similarly to a standard mandrel scraper, but it is fitted with a heavy-duty polyurethane disc or cup embedded with threaded ferrules uniformly arranged all around its circumferential faces into which a tungsten carbide pin or ceramic ball are mounted, similarly to a foam scraper.

Studded or pin-wheel scraper is designed purposely for the removal of scale and hard wax deposit from the pipeline’s internal wall. Aside from its primary purpose it also helps prolong the life of its discs/cups and serves as an alternative for suspension wheels if it will be used over long distance pipeline.

All studded or pin-wheel scrapers are supplied with by-pass ports which allow debris to be flushed ahead of the scraper. Other design options include the attachment of brushes, magnet boxes (for debris collection), and gauge plates for pipeline proving. All IKS scrapers are supplied with polyurethane bumper noses as standard.

All IKS scrapers are designed to pass minimum 1.5D radius bends and negotiate full bore branches. All IKS scrapers multi bolt scraper body assemblies are welded to code standard BS EN ISO 15614-1:2004+A1:2008.

View Technical Sheet PDFCopyrights © 2025 IKS All rights reserved.

Designed By: GulfTech